Homeowner’s Guide to Participating

If you are reading this, you may be considering participation in a program that subsidizes the installation of a different type of soil absorption system (or leachfield) that purportedly removes nitrogen from wastewater as the septic tank effluent percolates through it (a process called denitrification).

Under a grant from the EPA, Barnstable County will be allowed to subsidize and install a number of these experimental systems at homes throughout Southern New England. Likely questions by anyone considering this might be: “How do these systems differ from a standard leachfield?” or “What risk do I, as the homeowner, take on by installing this system?”

This page attempts to answer some of these questions, but in the final analysis, in the majority of instances there will be some risk. What follows is information by which you can make a decision regarding whether the potential benefits outweigh those potential risks.

Background

Over the past five years, researchers in various locations around the country have been investigating whether incorporating sawdust in various configurations while constructing a leachfield can enhance nitrogen removal by supplying this carbon source to support denitrification. These investigations follow upon more-demonstrated techniques for using wood-chips or sawdust for denitrification. For example, the Nitrex™ system, a proprietary in-tank system, uses woodchips contained in a tank and held in an anoxic condition following advanced treatment, thereby removing a high percentage of nitrate from wastewater.

Vertical reactive barriers (alternately called permeable reactive barriers or PRBs—illustrated below) have been used to mitigate nitrate by placing a column of woodchips as a permeable barrier that extends beneath the water table down-gradient to a groundwater plume containing nitrate. This causes a reduction of nitrate to harmless nitrogen gas as the plume passes through the barrier. After an extensive review of all the information that is available our staff sought to adapt these techniques to Cape Cod’s unique environment. There were some fundamental changes that were necessary as revealed by a series of soil column experiments (small simulated leachfields); however, these modifications seemed feasible.

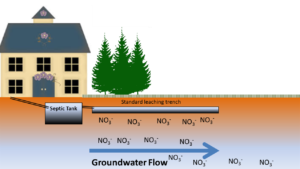

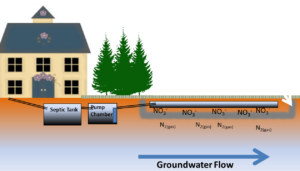

Three different designs of leachfield that incorporate sawdust have been placed at MASSTC and are currently being tested on a weekly basis. One design mimics experiments conducted in the early 90’s by University of Waterloo Professor Will Robertson. This design, illustrated below and contrasted with a standard septic system, introduces the same basic principle as the vertical barrier (PRB) previously discussed, but places the barrier in a horizontal configuration directly below the leaching component to intercept the nitrate-laden percolate.

If you are considering participation in this program, you probably have many questions. What follows is an attempt to answer the most commonly asked questions.

Frequently Asked Questions

Question. What are the major differences between a standard septic system and this alternative septic system?

Answer. The major components of a standard septic system include a septic tank (1500 gallon) and a gravity fed leachfield (≈600 sq. ft.). The alternative system has one added component which is a pump chamber (1000 gallon) and a timed-dose electrical panel.

Question. Besides components, what are the other differences between a standard system and this alternative?

Answer. A standard system generally requires a deep excavation (>5ft) for the leachfield. In the simplest of these experimental systems the wastewater is distributed in a shallow soil elevation (<8” below the surface). This in itself may be found to account for significant removal of nitrogen and phosphorus. Underneath the distribution network, there is 18 inches of sand, beneath which is placed a layer of sand and sawdust mixed at approximately a 60% sand to 40% sawdust by volume. Not all potential designs can be described in detail here, but these are the general “layers” comprising this system.

Question. How much electricity does the system use?

Answer. Assuming that the system will dose 10 times per day and run three minutes per dose with a 1kW pump and 18 cents/kWh (all very conservative assumptions), the cost of operation would be less than $40/year.

Question. Are there any other costs associated with maintaining the system that is beyond that of a “standard” system?

Answer. Septic tank effluent is distributed to the leachfield using a low-pressure distribution system which requires an annual maintenance visit/check. This may also require sampling to verify that the system is still working to remove nitrogen An approximate costs for these systems’ maintenance visit and monitoring is $250/year. During the first two years of operation, the costs of monthly monitoring are supported under the grant.

Question. About how much does this system cost compared to a standard “Title 5” system?

Answer. This depends on the situation, however the materials cost difference is estimated at $6,000 which includes the pump chamber and electrical panel (and installation) sand and sawdust purchase (no installation).

Question. Is there a subsidy for installing this system under the grant?

Answer. Yes, under the grant, up to $10,000 of allowable design and construction money will be reimbursed to all participants who present the receipts for work.

Question. What happens if the system fails to remove nitrogen to any degree?

Answer. Since we will not be installing these systems in any areas presently regulated for nitrogen, if the system fails to remove nitrogen, it should continue to hydraulically perform. Given the conservative nature of the designs, it is not expected to fail hydraulically, however if it does, the owner will be responsible for having a leachfield that complies with regulations which in some instances (see below) will mean additional costs.

Question. Is there anything a homeowner can do to minimize the risk?

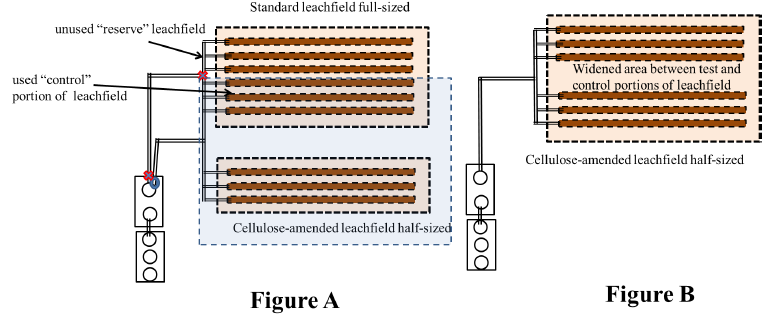

Answer. Presently, we are proposing two main means of installing these systems. In the ideal situation, we will install a full-sized “standard” low pressure dosed leachfield and a half-sized leachfield which is experimental (amended with lignocellulose—see Figure A below). In this instance, if the experimental leachfield experiences any hydraulic difficulties, we could merely discontinue its use by turning a few valves and a full-sized “normal” leachfield would be available for use, incurring no inconvenience to the homeowner.

If a prospective participant was willing to sign a waiver, then we would split a standard leachfield in half, widening the area between the halves and using one side of the leachfield as a standard and control system and the other as the test of the technology (See Figure B below). In situation “B” the home-owner may have to replace that portion of the leachfield that is experimental. In this latter scenario, the homeowner is assuming the risk and there is no subsidy for the replacement of the experimental portion of the system.

Remember: This system, like any septic system, requires that the owners take standard precautions regarding excessive flow due to leaks in the plumbing or allowing toxic chemicals to go down the drain. These may not only affect the nitrogen performance but may also result in an expensive repair bill.